Printing a bit of me - Bioprinting: Building living tissue with a 3D printer is becoming a new business, but making whole organs for transplant remains elusive - 3ecruit

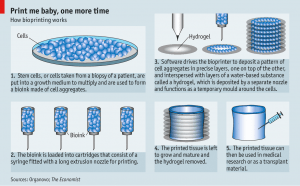

In a state-of-the-art clean room, a scientist clad in a full-body containment suit, a hair net and blue gloves is preparing some printing cartridges—filled not with ink but a viscous milky liquid. Next to her sits a computer connected to a machine that resembles a large ice-cream dispenser, except that each of its two nozzles is made of a syringe with a long needle. Once the scientist clicks on the “run program” button, the needles extrude not a vanilla or chocolate-flavoured treat, but a paste of living cells. These bioinks are deposited in precise layers on top of each other and interspersed with a gel that forms a temporary mould around the cells.

Forty minutes later, the task is finished. Depending on the choice of bioink and printing pattern, the result could have been any number of three-dimensional biological structures. In this case, it is a strand of living lung tissue about 4cm in length and containing about 50m cells.

Since its inception in 2007, researchers at San Diego-based Organovo have experimented with printing a wide variety of tissues, including bits of lung, kidney and heart muscle. Now the world’s first publicly traded 3D bioprinting company is gearing up for production. In January samples of its first product—slivers of human liver tissue—were delivered to an outside laboratory for testing. These are printed in sets of 24 and take about 30 minutes to produce, says Keith Murphy, the firm’s chief executive. Later this year Organovo aims to begin commercial sales.

Each set consists of a plate with 24 wells containing a piece of liver tissue 3mm square and 0.5mm deep. Although prices have not been fixed, a set of tissues like this can sell for $2,000 or more for laboratory use. It might seem expensive, but it could save pharmaceutical companies a lot of money. This is because Organovo’s research indicates that the slivers of liver respond to drugs in many ways like a fully grown human liver would. If this is confirmed by outside testing, researchers could use the printed tissues to test the toxicity of new drugs before deciding whether to embark on expensive clinical trials with patients.

The invention of 3D printing in the 1980s provided a technology now used to manufacture everything from aircraft parts to prosthetic limbs. But the promise of 3D bioprinting is even larger: to create human tissues—layer by layer—for research, drug development and testing, and ultimately as replacement organs, such as a kidney or pancreas, for patients desperately in need of a transplant. Bioprinted organs could be made from patients’ own cells and thus would not be rejected by their immune systems. They could also be manufactured on demand.

At present only a handful of companies are trying to commercialise the production of bioprinted tissues. But Thomas Boland, an early pioneer in the field, says that plenty of others are interested and estimates that about 80 teams at research institutions around the world are now trying to print small pieces of tissues as varied as skin, cartilage, blood vessels, liver, lung and heart. “It’s a wonderful technology to build three-dimensional biological structures,” says Gabor Forgacs, who co-founded Organovo in 2007 and was the company’s scientific mastermind.

Don’t hold your breath

Despite all this interest, the age of organ printing is not just around the corner. Not surprisingly, printing with living cells to create tissues is much more complex than printing objects in plastic or metal. Printing whole organs made from human cells was Dr Forgacs’s original idea when he started Organovo, but it has proved elusive. Yet he and other tissue engineers are hopeful that it will, one day, be possible.

Dr Boland started experimenting in the summer of 2000 using an old Lexmark inkjet printer that was sitting in his former lab at Clemson University in South Carolina. (He is now director of biomedical engineering at the University of Texas at El Paso.) At the time he wasn’t looking to print 3D biological structures, just proteins or cells in two-dimensional patterns. As it turned out, typical inkjet nozzles then were just large enough to accommodate most human cells, which tend to be around 25 microns in diameter (a micron is a millionth of a metre). “The printers at the time were really fulfilling all of the requirements that we would use for cell printing,” says Dr Boland.

Building additively

The potential of the technology quickly became apparent to other scientists. By the early 2000s, several research teams from different laboratories had begun to develop or modify printers to print cells in three dimensions. In Dr Boland’s case, he simply added to an HP printer a platform that could move up and down. In 2003 he filed for his first cell-printing patent and collaborated with Dr Forgacs and three other colleagues on a paper for Trends in Biotechnology in which they predicted that in this century “cell and organ printers will be as broadly used as biomedical research tools as was the electron microscope in the 20th century.” And in September 2004 the University of Manchester in Britain hosted the First International Workshop on Bioprinting and Biopatterning, with 22 speakers from ten countries.

Around the same time, Dr Forgacs began developing the technology that became the basis for Organovo. He devised a technique that could print a large number of cells at one time. Instead of an inkjet’s tiny nozzle that allows only droplets with individual cells to squeeze through, Dr Forgacs invented an extrusion-based printing process that uses a syringe with a needle or micropipette with an orifice that may be as large as several hundred microns. That made it possible to deposit large cell aggregates, in spheroid or cylindrical form. Pressure was applied to push them out, typically using an automated plunger.

Bioprinting is very different to standard tissue-engineering, in which cells are cultured and then seeded onto individual biodegradable moulds or scaffolds whose shapes resemble that of the organ or tissue they are replacing. Depending on the architectural needs of the organ and its function, a scaffold’s properties and structure need to vary as well, says Anthony Atala, a leader in this field and director of the Wake Forest Institute for Regenerative Medicine in North Carolina.

In the case of a blood vessel, the scaffold would have to be thin and elastic. “The scaffold really is acting like a prosthesis, like a device, until the cells are able to take over and lay down their own matrix,” Dr Atala explains. The timing of the scaffold’s demise is critical, he adds. If it degrades too quickly, the transplant is going to fail. But if it degrades too late, after the cells have made their own structure, the patient may end up with scarring.

Dr Atala and his team used to create scaffolds by hand and seeded the cells with a hand-held pipette. 3D printing helped to scale up the process, automate it and make it more precise because the printers run under computer control. His institute now has half-a-dozen 3D printers at its disposal, and in most cases researchers print the scaffold and the cells together. That way, says Dr Atala, “we could not just create one organ at a time, but create many organs at the same time.”

Organ and tissue structures vary in complexity, and some are much harder to make than others. From an architectural standpoint, flat structures, like skin or cartilage, are less complex than tubular ones, such as blood vessels or windpipes, says Dr Atala. Hollow, non-tubular organs, like the bladder, stomach or uterus, are trickier. But the most complex are relatively solid organs, such as the heart, liver or kidneys, which consist of many more cells and an extensive vascular structure.

Transplanted parts

So far, surgeons have been able to implant a variety of engineered flat, tubular and hollow tissues into patients, including skin, cartilage and muscle. Dr Atala has also successfully implanted lab-grown bladders and urethras into young patients. But solid organs are another matter. “That”, he says, “is really the next frontier.”

All tissue engineers have the same goal—to create human organs for transplant—but their approaches differ. In particular, they are divided on how much of a support structure or scaffold they need to provide for the cells, and what building materials are the most suitable.

Dr Forgacs believes that any type of scaffold interferes with a cell’s natural biology. His approach relies on the cells’ intrinsic ability to develop an innate shape and structure, which is akin to the differentiation and developmental processes that occur inside an embryo. Instead of a scaffold he uses what he calls “biopaper”, a water-based gel that is printed along with the bioink and surrounds the cell aggregates. Dr Forgacs calls this process “scaffold-free” bioprinting. The gel is not going to be part of the biological tissue, but a structure that holds the printed material together until the cell clusters themselves begin to fuse.

Because gels could interact with the cells, it is best to remove them quickly, usually in less than 24 hours, concurs Mr Murphy. “Our goal is to make something that’s 100% tissue as quickly as possible,” he says. In the case of Organovo, scientists do it by formulating the gel so they can dissolve it chemically or physically peel it off.

Brian Derby of the University of Manchester and author of a review in Science on printing tissues and scaffolds, emphasises that in some cases it is beneficial to use a scaffold. “People use scaffolds for a reason,” he says, “and that’s because gels have little or no structural integrity.” Rigid tissues, such as bone, require a structure that provides mechanical strength while the cells lay down their own matrix.

One of the biggest challenges facing tissue engineers is creating the necessary blood flow and vascular structure to supply organs with nutrients and oxygen, so they can thrive and survive in the long term. The heart and other solid organs in particular require an entire vascular tree, which is comprised of large blood vessels that branch into smaller and smaller vessels. So far, researchers have been able to make simple blood-vessel structures but not more complex vasculatures that could nourish solid organs.

Bioprinters could potentially construct a series of channels into each layer of cells, and these channels might be used to supply blood to tissue, says Dr Boland, who is working on the problem. His approach is to create hollow tubes from fibrin, a protein involved in blood clotting, surrounded by fat cells. On their inside, the tubes entrap endothelial cells, a type of cell that naturally forms blood vessels. The tubes serve as scaffolds for the cells, which—after being printed—go through a growing phase in an incubator. The structure is then implanted in mice and, if all goes well, connects up and integrates with surrounding tissues. If this approach works out, it could also prove useful for Dr Boland’s company, TeVido BioDevices, which aims to develop custom bioprinted implants and grafts for breast-cancer patients made from their own fat cells.

Organovo is licensing Dr Boland’s original cell-printing patent and has incorporated inkjet technology into its current systems (though the company will not disclose whether it plans to use it to help manufacture liver tissues). While Dr Forgacs’s extrusion process creates larger cell structures very quickly, one important feature of the inkjet-printing approach is its high resolution. It can be used to add detail and to apply thin layers of cells and patterns within layers, says Mr Murphy.

Several laboratories are currently working on developing bioprinters that could print skin cells directly onto wounds and burn injuries. At Wake Forest, researchers use a printer in conjunction with a laser to scan the size and depth of an injury. It produces a topological 3D map of the wound, which is used to determine how much material to deposit at any one spot, explains John Jackson, a member of Wake Forest’s skin-printing team.

Although the majority of bioprinters at Wake Forest are inkjet based, the researchers opted for a pressurised version. This is because of the difficulty of getting cells through the inkjet nozzle. “You get a lot of clogs,” says Dr Jackson. With the system they have chosen the researchers can change nozzle sizes, and the machine can print up to eight different types of cell. Recent studies on animals have shown that it is successful in printing precise layers of cells and cell types onto wounds. The process takes about 20-30 minutes for a wound that is around 10cm in length and width and up to 1cm deep.

The current treatment for burn patients is to take skin grafts from other areas of their body and transplant them onto the wounds. But the supply of skin from the body is limited, and the graft has to be prepared for transplantation. So, asks Dr Atala, why not save a step and print skin cells directly onto the patient? “The patient itself is the best incubator,” he believes. This process might also work for people with diabetes and for the elderly, whose wounds often do not heal well. Dr Jackson hopes, if things go according to plan, that the skin printer could be used in clinical trials within three or four years.

Dr Forgacs’s latest project does not involve bioprinting for medical purposes, but a simplified printing process to create meat for people to eat. When Organovo went public in 2012, he decided to leave the board (though he is still a consultant for the company) and devote more time to being chief scientific officer of Modern Meadow, a startup which he co-founded in 2011. As producing biomaterials for human consumption will probably involve lots of regulatory testing before any products can be brought to market, the company will initially concentrate on making leather (although not with a bioprinting process, but with some other form of biofabrication, says Dr Forgacs). Leather-goods manufacturers will be intrigued to see what he comes up with.

Dr Forgacs is hopeful that scientists will be able to build major organs eventually, although he does not believe they will ever be able to recreate a heart or kidney in the same minute detail as those organs exist inside the body. Instead he suggests researchers should look at building biological structures that function the same way. These will not look like the organs people have, he says, but they will be able to perform some of the same functions.

Mini organs

Organovo is conducting animal tests with structures that are not organs but smaller, patch-sized tissues that it can build. These structures could work like miniature organs and assist damaged tissue to function as normally as possible. For example, a heart-muscle patch could help repair the heart after a myocardial infarction. Or a patch could be used to bypass a blocked blood vessel. These are early-stage studies and no results have yet been disclosed. The company will evaluate a number of tissues which might be bioprinted as patches or mini organs, and then choose one or two with which it may proceed to clinical trials, possibly within the next five years, says Organovo’s Mr Murphy.

Ibrahim Ozbolat from the University of Iowa co-wrote a review of bioprinting and organ fabrication last year. He believes miniature organs are an important step towards creating fully functional organs, as they may be able to perform the most vital functions, such as the secretion of insulin to help the pancreas regulate glucose levels. The mini organs or patches may not cure patients, but could improve their quality of life. “The good news is the field is growing tremendously,” says Dr Boland. The arrival of the first products on the market will encourage more people to start working on bioprinting, and thus further breakthroughs.